Price Match

We guarantee our prices are extremely competetive and should be the BEST prices you will find on-line, along with delivering the very best service. For this reason, we offer a price match against other on-line sellers. If you find the same product elsewhere on line, give us a call on 0345 224 3691 and we will match or even beat it! Note that the following conditions must be met for the price match to apply:

- The item must be available on a UK website at the advertised price, and readily available to purchase, with a like for like delivery offering.

-The item in question must have the same specifications, quantity and be produced by the same manufacturer - although we will usually price match even if made by a different manufacturer, as long as its a comparable quality.

- Auction sites such as ebay and amazon do not qualify for price match.

- The price match cannot be used in conjunction with any discount codes or promotional items.

- If there are pricing errors on competitors sites that are clear typographical pricing errors, these will not be matched.

- Note that for corrugated lines (boxes/cartons), the item must be of the same specification (fluting and thickness) and be unbranded.

Call us on 0345 224 3691 and we will be more than happy to help!

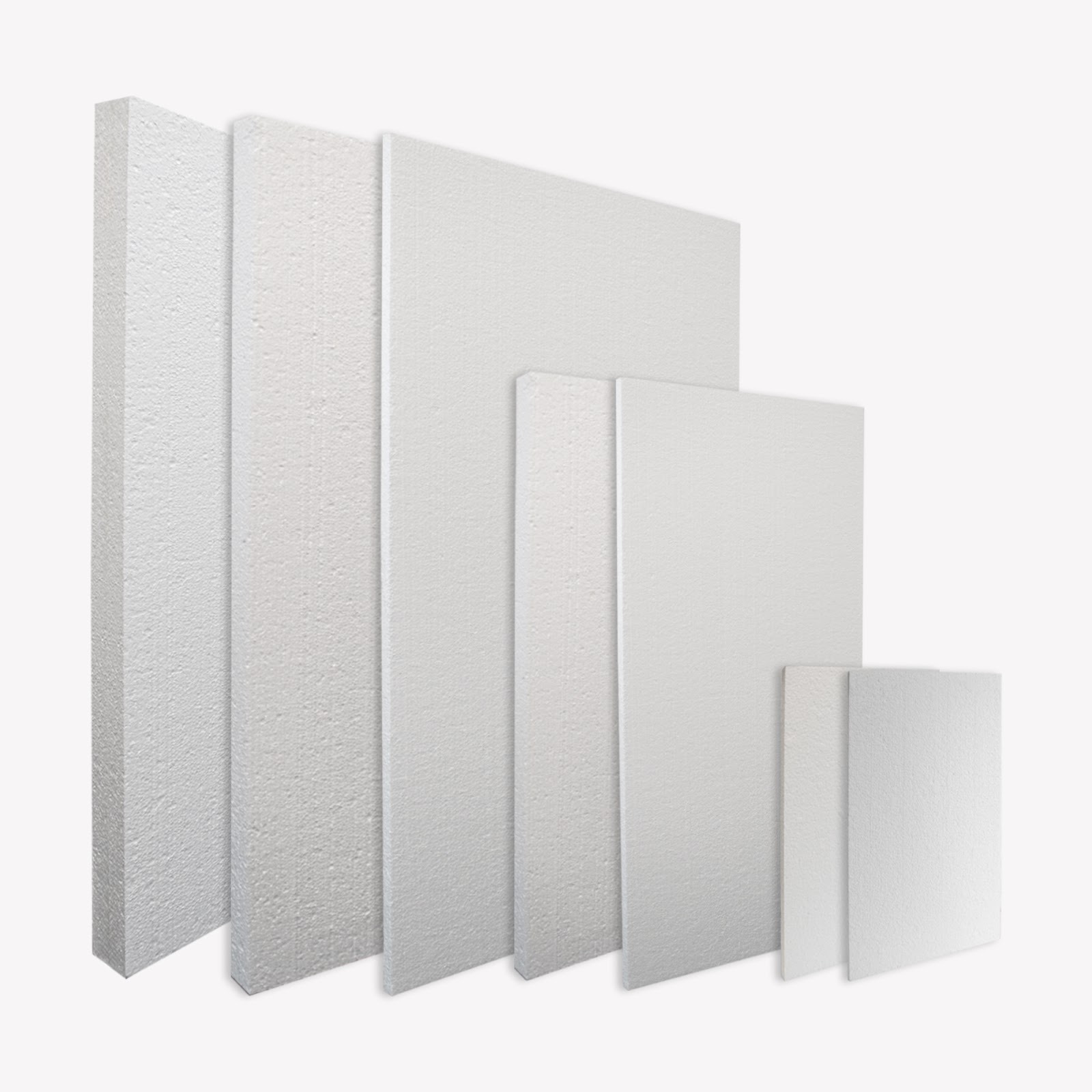

Polystyrene Sheets: Sizes, Cost & Use Cases

Key Takeaways

-

Polystyrene sheets typically cost between £3 and £25 per sheet, with pricing primarily determined by dimensions, thickness, and density grade.

-

Standard Expanded Polystyrene (EPS) sheet sizes include 2400x1200 mm, 1200x600 mm, and 600x400 mm, with thickness options ranging from 10 mm to 100 mm.

-

Bulk purchasing can reduce costs by 15–30% for large construction projects, making volume orders economically advantageous

-

Polystyrene sheets offer exceptional versatility across construction and packaging applications, from thermal insulation beneath floor screeds to protective packaging for fragile items, making them indispensable materials for diverse project requirements.

-

Globe Packaging provides comprehensive EPS70 inventory with next-day delivery, competitive volume-based pricing, and expert support to ensure optimal material selection.

Polystyrene Sheet Basics: What Construction Pros Need to Know

Polystyrene sheets come in two primary forms: expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS consists of small plastic beads fused, creating a lightweight material with approximately 98% air. This structure makes EPS an excellent insulator while remaining cost-effective for large-scale applications. XPS, meanwhile, has a more uniform closed-cell structure that provides enhanced moisture resistance and slightly higher R-values, though at a premium price point.

When selecting polystyrene sheets, density becomes a critical specification. EPS70 represents a grade with 15–16 kg/m³ density, providing sufficient compressive strength for most construction applications while remaining economical. Higher density grades like EPS100 (20 kg/m³) or EPS200 (30 kg/m³) offer increased load-bearing capacity for applications requiring greater structural support, albeit at higher price points.

For most general insulation and packaging applications, EPS70 delivers the optimal balance of performance and cost.

Standard Polystyrene Sheet Sizes Available in the Market

Common EPS Sheet Dimensions (2400x1200 mm and Others)

The most widely available polystyrene sheet size is 2400x1200 mm, corresponding to standard building material dimensions for efficient coverage of large areas. This size is particularly well-suited for wall and roof insulation applications, allowing contractors to cover substantial surface areas with minimal seams.

For smaller projects or areas with space constraints, 1200x600 mm sheets offer more manageable handling while maintaining compatibility with standard stud spacing and joist configurations. The compact 600x400 mm size provides excellent versatility for specialised applications, including packaging, void filling, and smaller insulation projects where precision cutting on-site would be inefficient.

Thickness Options from 10mm to 100mm

Polystyrene sheet thickness directly correlates with insulation performance and application requirements. Thinner sheets (10–25 mm) are typically used in applications where space is limited, but some thermal benefit is desired, such as internal wall insulation retrofits or packaging.

Mid-range thicknesses (50 mm) represent the sweet spot for many under-slab insulation applications, providing significant thermal performance while remaining cost-effective. Premium thermal performance requires thicker sheets (100 mm), which are increasingly specified for passive house construction and projects with stringent energy efficiency requirements.

Each incremental increase in thickness provides approximately proportional improvements in thermal resistance, though cost increases accordingly.

Cost Breakdown: What You'll Pay for Different Polystyrene Sheets

Understanding the cost structure of polystyrene sheets helps construction professionals budget effectively while selecting appropriate materials for their projects.

Price variations typically reflect differences in sheet dimensions, thickness, and density grade. Standard EPS70 sheets range from approximately £3 for smaller dimensions (600x400x10 mm) to £25 for larger, thicker options (2400x1200x100 mm), representing a significant variance that demands careful specification.

Material costs account for roughly 70% of the price of polystyrene sheet, with the remainder attributed to manufacturing processes, quality control, and distribution. This cost structure means that larger, thicker sheets offer better value per cubic metre of material, though they require higher upfront investment.

Bulk Purchase Savings for Large Projects

Construction or packaging projects requiring substantial volumes of polystyrene insulation can benefit significantly from economies of scale. Manufacturers generally establish tiered pricing structures that reduce per-unit costs as order quantities increase.

These volume discounts typically become meaningful at 100+ sheets, with substantial savings emerging at 500+ sheets. Consolidating polystyrene sheet orders across multiple project phases can unlock higher discount tiers even when immediate requirements are modest.

Practical Use of Polystyrene Sheets

Construction and Building

In construction, polystyrene sheets are the gold standard for insulation. EPS sheets are everywhere in modern buildings, tucked into walls, laid under roofs, and wrapped around foundations. They keep buildings warm in winter and cool in summer while slashing energy bills.

Beyond just keeping the temperature right, builders use polystyrene sheets as formwork for pouring concrete. They create voids in concrete slabs and foundations, which lightens the load without sacrificing strength. It's a smart trick that's especially useful in big commercial projects where every ton matters.

Packaging and Shipping

The packaging industry relies heavily on polystyrene sheets to protect fragile items during transit. Their shock-absorbing properties make them excellent for cushioning electronics, glassware, medical equipment, and other delicate products. Many manufacturers cut polystyrene sheets into custom shapes to create protective packaging inserts that fit precisely around products, minimising movement and potential damage.

Food service businesses use food-grade polystyrene sheets for disposable plates, trays, and containers. The material's insulating properties help maintain food temperature, whether hot or cold, while its lightweight nature reduces shipping costs for bulk orders.

Retail and Display

Retail environments extensively use polystyrene sheets for point-of-sale displays, shelf dividers, and product showcases. The material can be thermoformed into curved shapes, creating eye-catching displays that attract customer attention. Its lightweight nature allows for easy installation and reconfiguration as retail layouts change.

Exhibition designers also use polystyrene sheets to build temporary booth structures, wall panels, and display stands for trade shows. The sheets can be quickly assembled, decorated, and disassembled, making them economical for short-term events.

Specialised Applications

Polystyrene sheets serve specialised roles in industries such as photography, where they act as diffusers and reflectors for lighting setups. Greenhouse operators use them as glazing panels, taking advantage of their light transmission and insulation properties.

When selecting polystyrene sheets for your application, consider factors such as required strength, environmental exposure, regulatory compliance (especially for food-contact applications), and finishing requirements.

The material's versatility means that with proper specification, polystyrene sheets can effectively meet the demands of virtually any project requiring lightweight, durable, and economical sheet material.

Partner with Globe Packaging for Quality Polystyrene Solutions

Globe Packaging stands as your trusted partner for comprehensive EPS70 polystyrene sheet solutions. We maintain extensive stock across all thicknesses (10 mm–100 mm) and standard dimensions, ensuring immediate availability without project delays.

Our next-day delivery service across mainland UK supports tight construction schedules, while competitive volume-based pricing delivers cost savings for larger orders. Beyond competitive pricing, our support team provides expert guidance on density requirements, performance specifications, and application-specific challenges.

Whether you're sourcing insulation for residential foundations, commercial floor systems, or protective packaging for valuable construction materials, Globe Packaging combines product quality, competitive pricing, and responsive service to support your project success.

Shop With Globe Packaging Today →

Frequently Asked Questions

How do I determine the correct thickness of polystyrene sheet for my insulation project?

Thickness depends on thermal performance targets and available space. For under-slab residential insulation, 50mm sheets provide an excellent cost-to-performance balance. Passive house standards typically require a thickness of 75–100 mm. Space-constrained retrofits may need 25-mm options. Calculate required R-values based on climate zone and building energy targets.

Can polystyrene sheets withstand moisture in foundation applications?

Standard EPS70 sheets exhibit low water absorption by volume, maintaining approximately 95% thermal performance in high-humidity environments. They're suitable for most foundation applications when proper drainage prevents water accumulation. For extreme moisture conditions with high water tables, consider XPS alternatives offering enhanced resistance.

How should polystyrene sheets be stored on construction sites?

Store sheets flat on level, elevated surfaces to prevent warping and moisture damage. Keep covered with opaque tarps for UV protection. Limit stacks to 10–12 sheets maximum to avoid compression. Store away from heat sources, flames, and solvent-based materials-position in designated areas away from heavy equipment traffic. Properly stored polystyrene maintains full performance throughout construction schedules.

Why should I choose Globe Packaging for my polystyrene sheet requirements?

Globe Packaging delivers unmatched value through comprehensive inventory, competitive pricing, and reliable service. We stock all standard EPS70 dimensions and thicknesses (10 mm–100 mm) with next working day UK delivery. Our support team offers application-specific guidance on density, thermal specifications, and compatibility, making us your strategic partner for packaging solutions.

*Note: Prices shown are approximate and subject to change. Contact Globe Packaging for the latest information.

Accept

Accept Reject

Reject

Enjoy the May Bank Holiday!

Enjoy the May Bank Holiday!